- Coater

- High-efficient Sugar Coating/Film Coating Machine

- Changeable Coating Machine(I, II)

- Integrated coating machine

- Centrifugal Granulating Coating Machine

- Model ZTG Series Automatic Syrup Distribution Tank

- Granulating

- Model JHZ-D Series High-efficient Wet-process Granulator

- Model JFL Series High-efficient Boiling Granulator

- Model JFG-C Series High-efficient Boiling Drying Machine

- Model JHZ-K Series Lab Wet-process Granulator

- Model JYK Series Oscillating Granulator

- Model JFZ/B Series Grinding Granulator

- Model JZL Series Door Type Granulator

- Mixer

- 3-eccentricity Mixing Machine

- Single-arm multi-directional motion mixer

- Sterile mixing

- Model JHSD Series Laboratory Hopper Mixing Machine

- Model JHGD Series Fixed Square-taper Mixing Machine

- Model JHZD Series Auto-lift Hopper Mixer

- 3D Motion Mixing Machine

- Model JHTD Series Column Type Hopper Mixer

- Conversion operation

- Model JNTFZ Series Fixed Feeder & Granulator

- Model JNTF Series Fixed Lifting Feeder

- JZLT Series Lifting Granulator

- Model JNTD Series Hopper Charging Elevator

- Model JYT Series Movable Feeder

- Model JNTC Series Interlayer Elevator

- Conversion operation

- Model JGF-B Series High-efficient Grinder

- Model JGF-C Series High-efficient Grinder

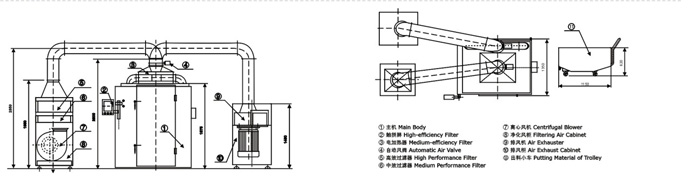

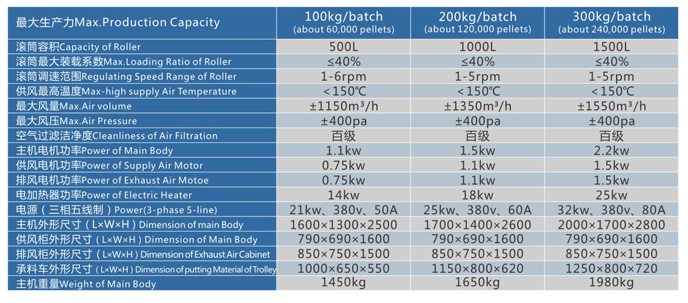

Multi-function Dynamic Drying Machiner

JGDG type high efficient dynamic dryer is the company through years of careful development of successful domestic most advanced material dynamic drying equipment. The equipment is suitable for various rubber plug, pills, candy and other items and drying; high temperature sterilization function, is a kind of reasonable design, high efficiency and energy saving, compact structure, easy to operate a new drying equipment. To meet the food medicine industry GMP.

JGDG type high efficient dynamic dryer is the company through years of careful development of successful domestic most advanced material dynamic drying equipment. The equipment is suitable for various rubber plug, pills, candy and other items and drying; high temperature sterilization function, is a kind of reasonable design, high efficiency and energy saving, compact structure, easy to operate a new drying equipment. To meet the food medicine industry GMP.

the dry material in the closed double tapered roller diameter guide plates, continuous complex slow roll (i.e., predicate dynamic drying ). At the same time drop after heating the clean air input roller, which penetrate into the family bed space diffusion, and through the bottom of the drum of the best exhaust location negative pressure, the moist gas and air exhaust, the whole process in the machine set procedures complete; can finish the drying purposes, and can rise to high temperature sterilization effect of the material, fast, uniform color, the best drying effect.

The host drum using porous plate by double vertebral structures, internal flat and smooth, no dead angle.

Drum double vertebral angles and special guide plate shunt, so that the material produced in the operation of cross dislocation motion, so as to obtain a quick, even the best dynamic drying effect.Using PLC programmable system control, touch screen operation (HMI ), dynamic display; a high degree of automation, convenient operation, long service life.For the butterfly valve, inlet and outlet automatic control, air temperature, air pressure to help balance change function, improve the drying effect.

Hot air from the top into the host, can rapidly penetrate into the material bed spread, while exhaust outlet in the bottom of the roller, through the negative pressure space of damp and cold air exhaust fan.

The heat energy can be fully utilized, not to waste; also greatly improves the drying speed of the material.Process data, supply, exhaust volume, temperature, time and other curves recorded automatically, even if the print.

Electric heater temperature control by the microcomputer automatic segmentation, PID mode control, greatly improving the utilization rate of electric energy.

Configuration of variable frequency speed regulation, conducive to the production process and the adjustment of inlet, outlet, cleaning and other operational requirements.

The host box using double insulation structure, improve the protective equipment integrity.

The hinge type door open, high strength, convenient operation, cleaning.

In a special guide plate under the action of the material, can be automatically unloaded.

Equipment appearance and all parts in contact with the parts all use high-quality stainless steel materials

Equipped with two charging trolley with cover bearing, bearing skip directly into the host for the material, avoids cross infection, easy to use.

Equipment appearance, compact structure, small occupation area, convenient and safe.

Conventional ( capsule ) drying time: 120~180 / batch moisture content: <0.05%

Please feel free to contact with us at jp@cnjianpai.com or filling up an enquiry form instructed at the bottom, You will get an effective response within 24 hours from Shengyuan sales representative. Thanks for your valued time with interest!